The Critical Role of Traceability in Textile Production

In our series, “Creating a Critical Mass in the Textile Sustainability Movement,” we’ve had insightful conversations with many industry experts. One recurring theme is the critical role of traceability in textile production, which ties directly into understanding and reducing greenhouse gas emissions, including Scope 1, Scope 2, and Scope 3 emissions. Traceability helps consumers know where their products come from and enables brands to align their operations with sustainability goals by measuring and managing their carbon footprint.

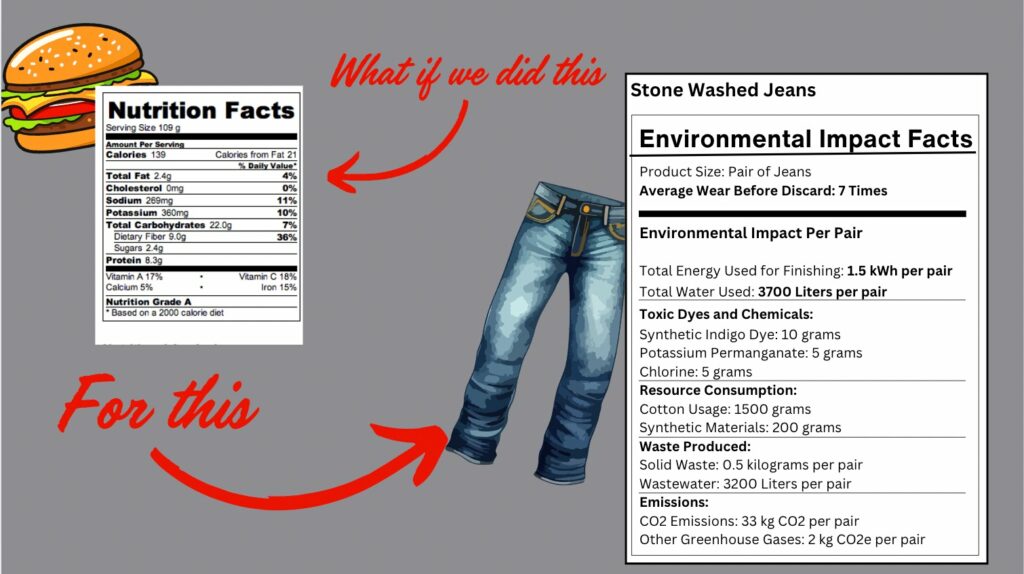

Caption: Imagine if our clothes were treated similarly to the food we consume, and came with a detailed label accurately describing the impact our purchases have on the environment. NOTE: All data in the image are for illustrative purposes only.

In this article, we will explore the importance of traceability, the challenges in achieving it, the need for understanding the entire production process, and NTX’s approach to accountability and traceability.

The Importance of Traceability in Textile Production

Traceability in textile production is essential for both consumers and brands. It provides a transparent view of the journey from raw material to finished product, addressing Scope 1 (direct emissions from owned or controlled sources), Scope 2 (indirect emissions from the generation of purchased electricity), and Scope 3 emissions (all other indirect emissions that occur in a company’s value chain). This transparency is increasingly demanded by a conscious consumer base and is critical for brands aiming to uphold their sustainability commitments.

Consumer Awareness:

- Traceability helps consumers know the origin of their products, ensuring they are made ethically and sustainably.

- There is a growing demand among consumers for transparency and ethical production, influencing their purchasing decisions.

Brand Alignment:

- Brands can ensure their supply chain partners share their sustainability goals, creating a cohesive and ethical production line.

- This alignment benefits brands in terms of reputation and builds consumer trust, fostering long-term loyalty.

Challenges of Achieving Traceability

Achieving traceability in textile production is challenging due to the complex nature of supply chains, often divided into tier 1 (garment suppliers), tier 2 (fabric suppliers), and tier 3 (raw material suppliers). Brands typically lack direct control over these tiers, making consistent traceability difficult. Tier 2 and tier 3 suppliers involve many more players than tier 1, complicating the collection of detailed information about all the factories involved.

The apparel supply chain is more intricate than the commonly known stages of fiber, yarn, fabric, and garment manufacturing. Components like yarns, fabrics, sewing threads, buttons, and zippers each have their own complex sub-supply chains involving multiple facilities worldwide. This complexity necessitates a comprehensive understanding of the entire supply chain to ensure overall traceability.

Raw material commoditization adds another layer of difficulty. Materials are often mixed from various sources, complicating tracking and tracing their origins. Using recycled textiles introduces additional challenges, such as higher transportation costs due to the more involved collection process. These factors highlight the significant obstacles brands face in achieving full traceability within their supply chains, emphasizing the need for detailed oversight and management.

The Importance of Understanding the Entire Production Process

Understanding the entire production process is crucial for evaluating not just where materials come from but also the efficiency and sustainability of supplier operations. This includes measuring Scope 1 emissions from supplier operations, Scope 2 emissions from energy use, and Scope 3 emissions from the broader supply chain.

Efficiency of Suppliers

It’s essential to consider the overall efficiency and sustainability of suppliers’ operations, beyond the origin of raw materials. For example, poor forecasting by a brand can lead to overproduction and waste throughout the supply chain, highlighting the need for comprehensive evaluation. Brands should consider how to work closely with their suppliers to alleviate this problem.

Resource-Intensive Processes

Processes such as coloration and finishing involve various chemicals and efficiencies, leading to different levels of wastewater production and resource consumption. Understanding these processes is vital for assessing their environmental impact and improving sustainability.

NTX®‘s Approach to Accountability and Traceability

From our very beginning, NTX® has been committed to enhancing accountability and traceability through strategic collaborations and innovative practices. Our principal technology NTX® Cooltrans® was designed from the ground up to transform the textile coloration process into a more sustainable and environmentally friendly process.

Collaboration with Third Parties:

- We work with organizations like the Sustainable Apparel Coalition, utilizing the Higg Index to measure and improve our sustainability performance. Our successful implementation of these practices is evident in the low impact Higg Index scores of our coloration processes for Nylon and Polyester, demonstrating our commitment to sustainability.

- Partnering with Bluesign® helps us manage chemical usage and ensure safety in our production processes.

Beyond third party verification partners, we continually work on making our technology more efficient and agile. One often overlooked aspect of NTX® Cooltrans® is the ability to execute designs faster making it the ideal coloration system for an industry that is continuously shortening production lead time requirements.

Traceability in textile production is vital for ensuring ethical practices and sustainability. NTX® is dedicated to achieving high standards of traceability, working with reputable third parties and adopting innovative strategies. We encourage brands and consumers to support initiatives that promote transparency and sustainability in the textile industry, paving the way for a more responsible and ethical future.